|

|

Loss reduced constructions as a step towards a decreased energy consumption

|

|

|

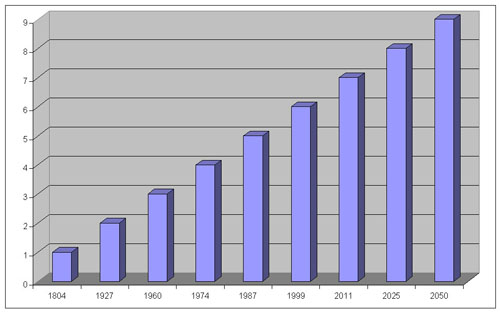

The on and on growing population growth and the associated consumption of energy requires energy efficient products to cover the high energy consumption. According to a survey the EU has ca. 4,6 million power transformers. These cause losses of around 39 TWh per year - this matches approximately the energy consumption of a small country - and furthermore they cause a carbon dioxide emission of ca. 37 million tons a year. By using energy-efficient power transformers, these losses can be reduced significantly and thus the efficiency increases. To reduces the losses that occur in transformers is an essential part of new developments nowadays. Back in the days the purchase prize was the most significant, today the whole life-cycle cost is of high importance. By using energy saving power transformers losses can be reduces significantly and thus the efficiency increases.

|

|

|

|

|

|

Power loss in a transformer

|

|

|

The power loss in a transformer can be divided in two sections:

- no-load losses (caused by a changeing magnetization and eddy currents in the core) = iron losses

- load losses (caused by ohmic losses in the conductors, which will increase quadratic proportional with the charges) = copper losses

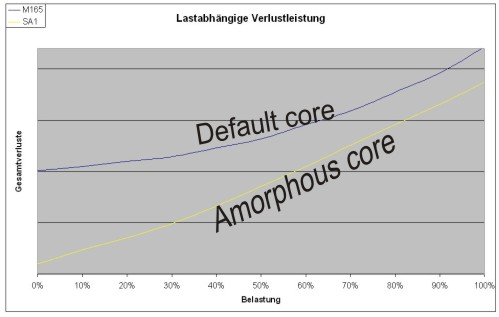

By using amorphous core material the iron losses can be reduced significantly. As this material has to be operated with lower induction, more copper is necessary and consequently the copper losses are higher. Though in total the overall losses are less than in normal transformer metal sheets. The use of amorphous core material is of interest for efficient power transformers as the amount of iron losses can be reduced significantly compared to the standard transformer metal sheets.

These transformers are rarely operated with full load (thus the low copper losses). This is also why the total losses are way lower than for transformers with default cores made of metal sheets (see diagram).

|

|

|

|

|

|

An amorphous solid is an object that is not structured like a crystal grid. Here the atoms don’t have an organized pattern but an irregular structure. There is no long-range-order.

A crystalline solid is an object that is structured like a crystal grid. Here you have a recognizable, repetitive pattern.

|

|

|

Example: 3-phase transformer 200 kVA

|

|

|

Operation with 20% load:

- total losses default core: ca. 1200 W

- total losses amorphous core: ca. 450 W

→ Savings of ca. 750 W, this means a saving of 18 kWh at a 24 h permanent operation

→ At an electricity price of 0,20 €/kWh this is a saving of around 1314 € per year

Conclusion: Compared to the default core the amorphous core costs a bit more. Depending on the size of the transformer, this price can amortize within 2-4 years. In this term you can not only save energy but also money. During the lifetime of the transformer the savings can be a multiple of the investment costs. Due to the energy-efficient and thus low-loss construction, these transformers can also be enclosed in hermetic housings as they have less heating.

Remark: In some cases an oversizing on purpose can add to saving valuable energy. These transformers are only operated with partial load and thus can make use of the advantages of low losses. A maybe higher cost price can pay itself off after a short duration already.

|

|

|

Energy-efficient 3-phase transformers up to 30 kVA

|

|

|

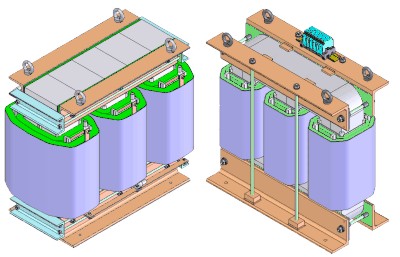

The amorphous cores show their advantages concerning reduced losses only with big power transformers. Small power transformers only have a small improvement of energy-efficiency due to the higher amount of copper and the associated higher copper losses.

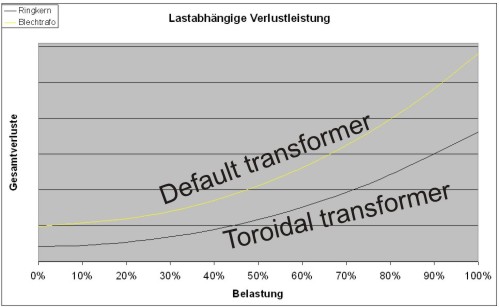

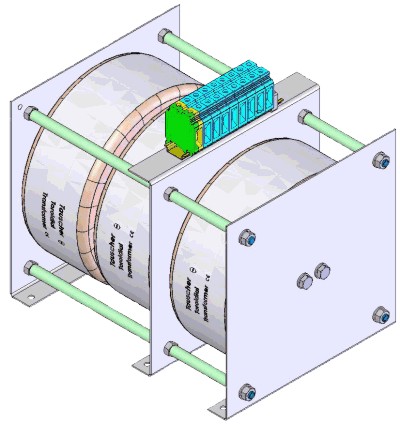

Energy-efficient threephase systems in a power range up to 30 kVA can be built up with toroidal transformers. The array of the tape material (barely airgaps, low magnetostriction) makes this construction very low on losses and hence it is an alternative for 3-phase systems with default core material.

Merely an additional wiring to limit the high start-up current is needed for transformers of this size. The following diagram shows a direct comparison of 30 kVA three phase transformers with default transformer metal sheets and three phase toroidal transformers.

|

|

|

|

|

|

Reduction of idle power due to usage of energy-efficient transformers

|

|

|

The following table shows three-phase transformers of various power classes and their idle power losses.

|

|

|

|

Transformer size

|

Power [kVA]

|

Idle power [Var]

|

Default/Amorphous

|

|

Amorphous core

|

S3U 500/500/150

|

63

|

1405

|

2,6

|

|

Default core

|

EI 500/500/150

|

63

|

3690

|

|

|

|

|

|

|

|

Amorphous core

|

S3U 500/500/175

|

80

|

2890

|

2,2

|

|

Default core

|

EI 500/500/175

|

80

|

6226

|

|

|

|

|

|

|

|

Amorphous core

|

S3U 500/500/200

|

95

|

3950

|

2,4

|

|

Default core

|

EI 500/500/200

|

100

|

7025

|

|

|

|

|

|

|

|

Amorphous core

|

S3U 600/600/150

|

125

|

2450

|

3,0

|

|

Default core

|

EI 600/600/150

|

125

|

7379

|

|

|

|

|

|

|

|

Amorphous core

|

S3U 600/600/200

|

160

|

3420

|

2,9

|

|

Default core

|

EI 600/600/200

|

160

|

9891

|

|

|

|

|

|

|

|

Amorphous core

|

S3U 700/700/200

|

200

|

3404

|

2,5

|

|

Default core

|

EI 700/700/200

|

200

|

8510

|

|

|

|

|

|

|

|

Amorphous core

|

S3U 800/800/160

|

300

|

3540

|

2,2

|

|

Default core

|

EI 800/720/160

|

300

|

7870

|

|

|

|

|

Conclusion: By using amorphous core material, the amount of idle power losses can be reduced by an average factor of 2,5.

|

|